Minimax Metals & Plywood Pvt. Ltd.

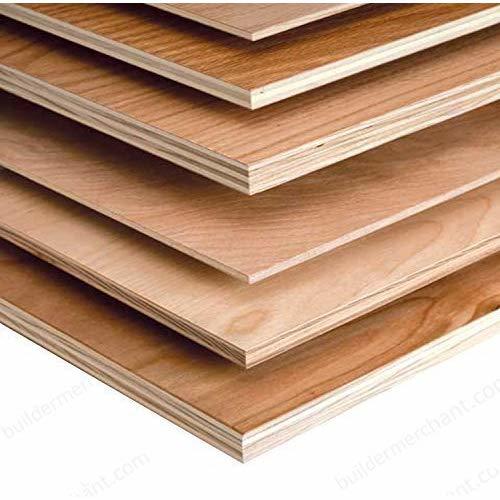

Marine plywood

We are catering to the demand of plywood since last two decades and are constantly improving the quality of our plywood. Our professionals do understand that marine plywood needs to show excellent resistivity to moisture and water. That is why; they are utilizing best quality adhesives to ensure water resistivity in them. At Minimax Plywood, we aim to design and craft marine plywood which can easily withstand the exposure to humidity or water with ease. We source premier grade hardwood veneers for fabricating the marine grade plywood. We ensure that all our hardwood veneers are free of voids and gaps making them robust quality plywood. For producing the waterproof and boiling proof plywood, we bind them with waterproof adhesives exclusively made for binding marine plywood.

Our marine grade plywood comes in multiple shapes and sizes and their thickness also varies according to the different needs of this plywood. Our craftsmen arrange and layer the hardwood veneers in a way that they show excellent strength. We offer smooth surface and well finished marine plywood that requires minimum maintenance. We have an extensive manufacturing unit where we produce this plywood in bulk quantity by utilizing innovative tools and technology. At Minimax Plywood, our priority is to deliver marine plywood with exceptional structural integrity. We treat this plywood with best chemicals to make it rot and fungal resistant for better performance.

We always craft this plywood by considering industrial and quality standards to ensure that all the industrial criteria are met when fabricating these. Our impeccable quality and promise to deliver 100 percent authentic marine plywood has made us one of the top rated marine plywood manufacturers in India. Minimax Plywood is one of the ISO verified plywood manufacturers which has captured the Indian market with its exceptional quality marine grade plywood. We have quality testing units for each process starting from the sourcing of hardwood veneers to manufacturing and packaging it. It helps us maintain quality in each step ensuring that we deliver satisfying marine plywood to our customers.

At present, we are supplying marine plywood for several applications including bathroom cabinets, kitchen countertops, boat building, benches for parks, ship construction, decks, porches, patios, construction of furniture for ships and boats, and several other applications. We are offering marine plywood at budget friendly prices in both small and large quantity to our customers.

Test Result

| S.NO.TEST | I.S.I REQUIREMENT | TEST RESULT |

|---|---|---|

| 1. Moisture Content | 5-15% | 7.5% |

| 2. Glue Shear Strength in Dry Condition | a) Individual Average Min. 1100 Newton b) Average Min. 1100 Newton 1350 Newton | 1400 Newton 1590 Newton |

| 3. Glue Shear Strength in Wet Condition | a) Individual 800 Newton b) Average Min. 1000 Newton | 1080 Newton 1360 Newton |

| 4. Glue Shear Strength in Mycological Test | a) Individual 800 Newton b) Average Min. 1000 Newton | 1090 Newton 1350 Newton |

| 5. Tensile Strength a) Parallel to grain direction b) Right angle to grain direction c) Sum of both directions | 42.0N/mm2 25.0N/mm2 84.5N/mm2 | 645 KN/M2 395 KN/M2 1040 KN/M2 |

| 6. a) MOR N/MM2 b) Parallel to grain c) Perpendicular to grain | Avg./Min50/45 30/27 | 60/5540/35 |